What is Reverse Osmosis? (RO) part 2

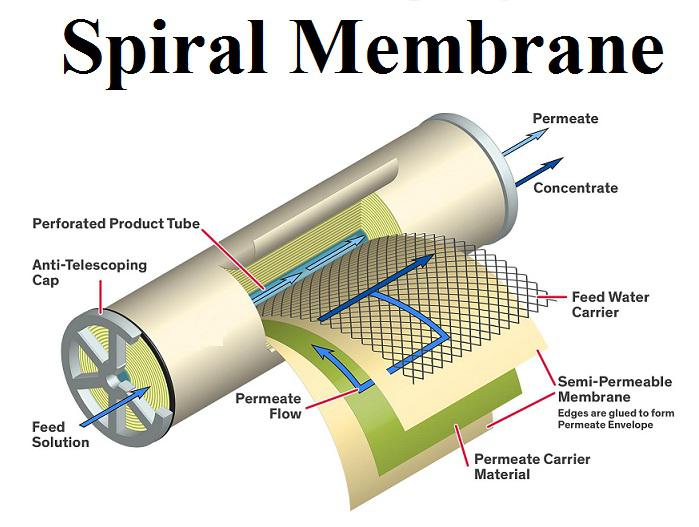

Reverse Osmosis is a technology that is used to remove a large majority of contaminants from water by pushing the water under pressure through a semi-permeable membrane.

This article is aimed towards an audience that has little or no experience with Reverse Osmosis water and will attempt to explain the basics in simple terms that should leave the reader with a better overall understanding of Reverse Osmosis water technology and its applications.

Reverse Osmosis (RO) system: Understanding the difference between passes and stages in a Reverse Osmosis (RO) system

The terms stage and pass are often mistaken for the same thing in an RO system and can be confusing terminology for an RO operator. It is important to understand the difference between a 1 and 2 stage RO and a 1 and 2 pass RO.

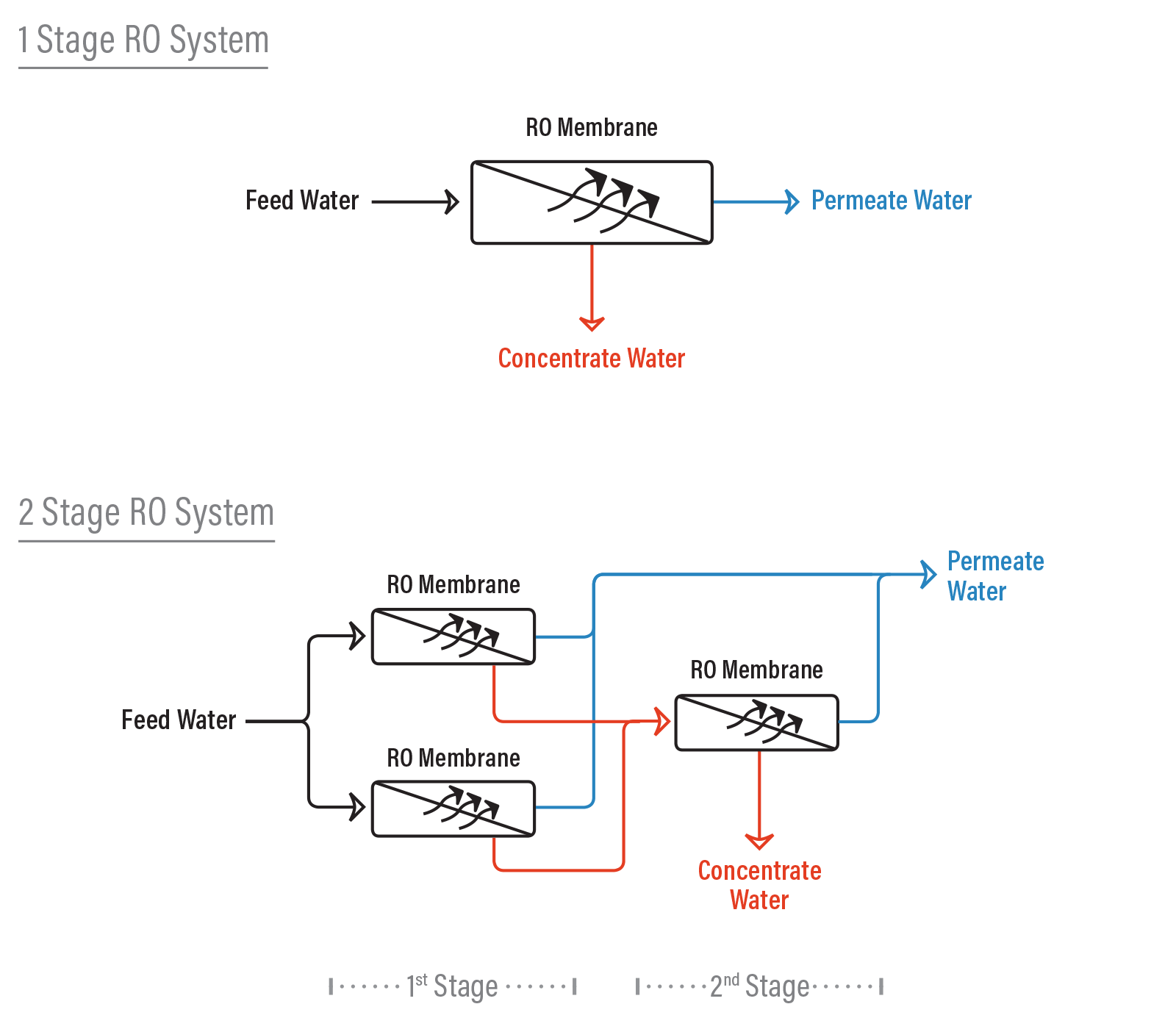

DIFFERENCE BETWEEN A 1 AND 2 STAGE RO SYSTEM

In a one stage RO system, the feed water enters the RO system as one stream and exits the RO as either concentrate or permeate water.

In a two-stage system the concentrate (or reject) from the first stage then becomes the feed water to the second stage. The permeate water is collected from the first stage is combined with permeate water from the second stage. Additional stages increase the recovery from the system.

Array

In a Reverse Osmosis System an array describes the physical arrangement of the pressure vessels in a 2 stage system. Pressure vessels contain RO membranes (usually from 1 to 6 RO membranes are in a pressure vessel). Each stage can have a certain amount of pressure vessels with RO membranes. The reject of each stage then becomes the feed stream for the next successive stage. The 2 stage RO system displayed on the previous page is a 2:1 array which means that the concentrate (or reject) of the first 2 RO vessels is fed to the next 1 vessel.

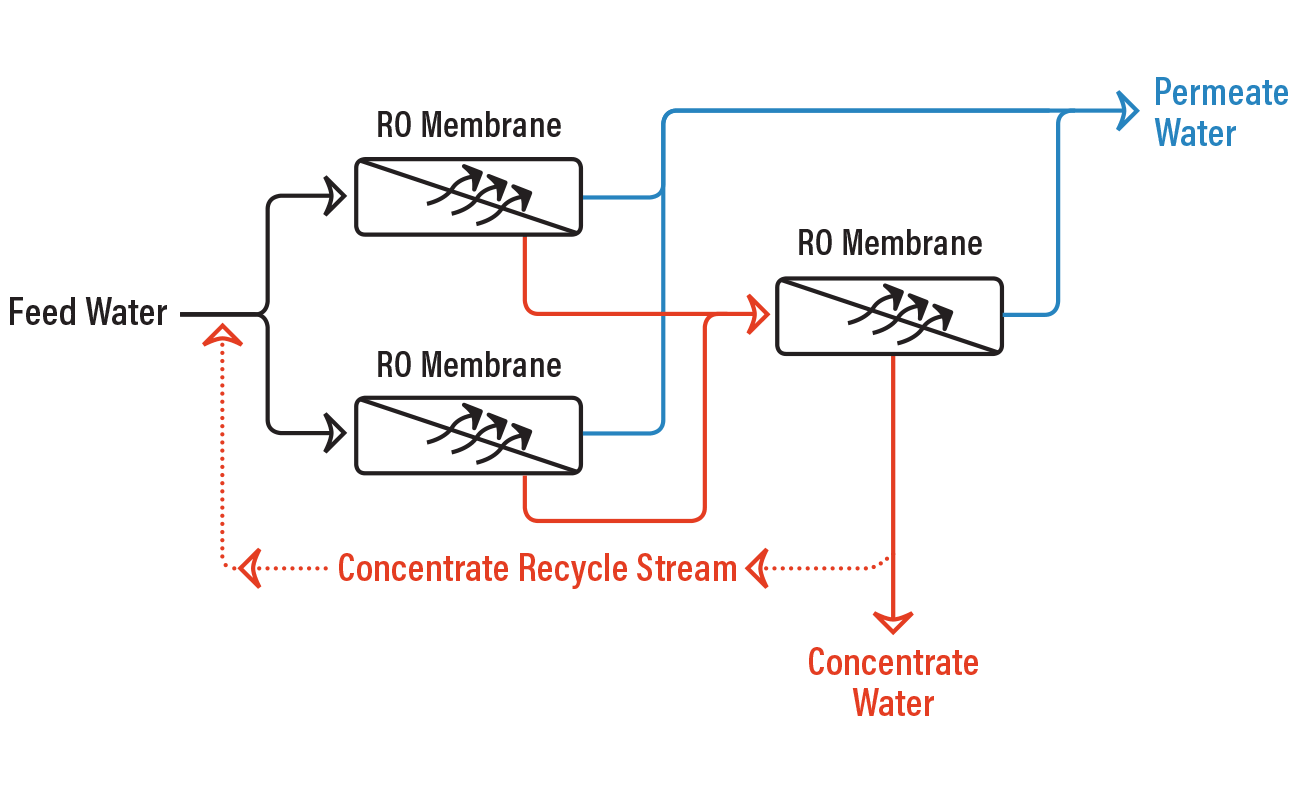

RO SYSTEM WITH CONCENTRATE RECYCLE

With an RO system that can’t be properly staged and the feed water chemistry allows for it, a concentrate recycle setup can be utilized where a portion of the concentrate stream is fed back to the feed water to the first stage to help increase the system recovery.

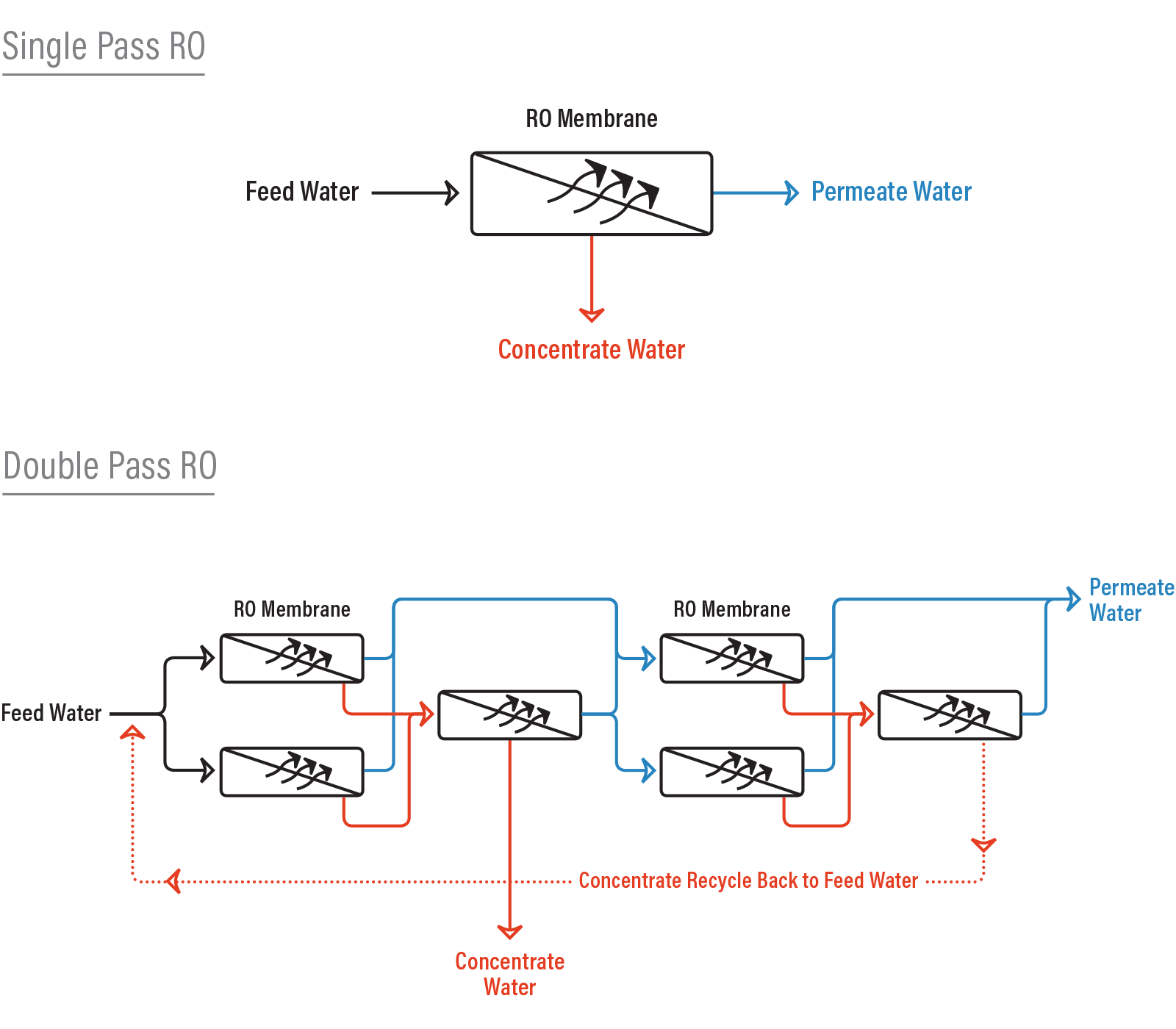

SINGLE PASS RO VS DOUBLE PASS RO

Think of a pass as a stand alone RO system. With this in mind, the difference between a single pass RO system and a double pass RO system is that with a double pass RO, the permeate from the first pass becomes the feed water to the second pass (or second RO) which ends up producing a much higher quality permeate because it has essentially gone through two RO systems.

Besides producing a much higher quality permeate, a double pass system also allows the opportunity to remove carbon dioxide gas from the permeate by injecting caustic between the first and second pass. C02 is undesirable when you have mixed bed ion exchange resin beds after the RO. By adding caustic after the first pass, you increase the pH of the first pass permeate water and convert C02 to bicarbonate (HCO3-) and carbonate (CO3-2) for better rejection by the RO membranes in the second pass. This can’t be done with a single pass RO because injecting caustic and forming carbonate (CO3-2) in the presence of cations such as calcium will cause scaling of the RO membranes.

RO Pretreatment

Proper pretreatment using both mechanical and chemical treatments is critical for an RO system to prevent fouling, scaling and costly premature RO membrane failure and frequent cleaning requirements. Below is a summary of common problems an RO system experiences due to lack of proper pretreatment.

Fouling

Fouling occurs when contaminants accumulate on the membrane surface effectively plugging the membrane. There are many contaminants in municipal feed water that are naked to the human eye and harmless for human consumption, but large enough to quickly foul (or plug) an RO system. Fouling typically occurs in the front end of an RO system and results in a higher pressure drop across the RO system and a lower permeate flow. This translates into higher operating costs and eventually the need to clean or replace the RO membranes. Fouling will take place eventually to some extent given the extremely fine pore size of an RO membrane no matter how effective your pretreatment and cleaning schedule is. However, by having proper pretreatment in place, you will minimize the need to address fouling related problems on a regular basis.

Fouling can be caused by the following:

- Particulate or colloidal mater (dirt, silt, clay, etc.)

- Organics (humic/fulvic acids, etc)

- Microorganisms (bacteria, etc). Bacteria present one of the most common fouling problems since RO membranes in use today cannot tolerate a disinfectant such as chlorine and therefore microorganisms are often able to thrive and multiply on the membrane surface. They may produce biofilms that cover the membrane surface and result in heavy fouling.

- Breakthrough of filter media upstream of the RO unit. GAC carbon beds and softener beds may develop an under drain leak and if there is not adequate post filtration in place the media can foul the RO system.

By performing analytical tests, you can determine if the feed water to your RO has a high potential for fouling. To prevent fouling of an RO system, mechanical filtration methods are used. The most popular methods to prevent fouling are the use of multi-media filters (MMF) or microfiltration (MF). In some cases cartridge filtration will suffice.

Scaling

As certain dissolved (inorganic) compounds become more concentrated (remember discussion on concentration factor) then scaling can occur if these compounds exceed their solubility limits and precipitate on the membrane surface as scale. The results of scaling are a higher pressure drop across the system, higher salt passage (less salt rejection), low permeate flow and lower permeate water quality. An example of a common scale that tends to form on an RO membrane is calcium carbonate (CaCO3).

Chemical attack

Modern thin film composite membranes are not tolerant to chlorine or chloramines. Oxidizers such as chlorine will ‘burn’ holes in the membrane pores and can cause irreparable damage. The result of chemical attack on an RO membrane is a higher permeate flow and a higher salt passage (poorer quality permeate water). This is why microorganism growth on RO membranes tends to foul RO membranes so easily since there is no biocide to prevent its growth.

Mechanical damage

Part of the pretreatment scheme should be pre and post RO system plumbing and controls. If ‘hard starts’ occur mechanical damage to the membranes can occur. Likewise, if there is too much backpressure on the RO system then mechanical damage to the RO membranes can also occur. These can be addressed by using variable frequency drive motors to start high pressure pumps for RO systems and by installing check valve(s) and/or pressure relief valves to prevent excessive back pressure on the RO unit that can cause permanent membrane damage.

Pretreatment solutions

Below are some pretreatment solutions for RO systems that can help minimize fouling, scaling and chemical attack.

Multi media filtration (MMF)

A Multi-Media Filter is used to help prevent fouling of an RO system. A Multi-Media Filter typically contains three layers of media consisting of anthracite coal, sand and garnet, with a supporting layer of gravel at the bottom. These are the media of choice because of the differences in size and density. The larger (but lighter) anthracite coal will be on top and the heavier (but smaller) garnet will remain on the bottom. The filter media arrangement allows the largest dirt particles to be removed near the top of the media bed with the smaller dirt particles being retained deeper and deeper in the media. This allows the entire bed to act as a filter allowing much longer filter run times between backwash and more efficient particulate removal.

A well-operated Multi-Media Filter can remove particulates down to 15-20 microns. A Multi-Media Filter that uses a coagulant addition (which induces tiny particles to join together to form particles large enough to be filtered) can remove particulates down to 5-10 microns. To put this in perspective, the width of a human hair is around 50 microns.

A multi media filter is suggested when the Silt Density Index (SDI) value is greater than 3 or when the turbidity is greater than 0.2 NTU. There is no exact rule, but the above guidelines should be followed to prevent premature fouling of RO membranes.

It is important to have a 5 micron cartridge filter placed directly after the MMF unit in the event that the under drains of the MMF fail. This will prevent the MMF media from damaging downstream pumps and fouling the RO system.

Microfiltration (MF)

Microfiltration (MF) is effective in removing colloidal and bacteria matter and has a pore size of only 0.1-10µm. Microfiltration is helpful in reducing the fouling potential for an RO unit. Membrane configuration can vary between manufacturers, but the “hollow fiber” type is the most commonly used. Typically, the water is pumped from the outside of the fibers, and the clean water is collected from the inside of the fibers. Microfiltration membranes used in potable water applications usually operate in “dead-end” flow. In dead-end flow, all of the water fed to the membrane is filtered through the membrane. A filter cake that must be periodically backwashed from the membrane surface forms. Recovery rates are normally greater than 90 percent on feed water sources which have fairly high quality and low turbidity feeds.

Xem thêm bài viết lọc tinh là gì? hướng dẫn thay lõi lọc tinh

Antiscalant and scale inhibitors

Antiscalants and scale inhibitors, as their name suggests, are chemicals that can be added to feed water before an RO unit to help reduce the scaling potential of the feed water. Antiscalants and scale inhibitors increase the solubility limits of troublesome inorganic compounds. By increasing the solubility limits, you are able to concentrate the salts further than otherwise would be possible and therefore achieve a higher recovery rate and run at a higher concentration factor. Antiscalants and scale inhibitors work by interfering with scale formation and crystal growth. The choice of antiscalant or scale inhibitor to use and the correct dosage depends on the feed water chemistry and RO system design.

Xem thêm bài viết: Antiscalant là gì?

Softening by ion exchange

A water softener can be used to help prevent scaling in an RO system by exchanging scale forming ions with non scale forming ions. As with a MMF unit, it is important to have a 5 micron cartridge filter placed directly after the water softener in the event that the under drains of the softener fail.

Sodium Bisulfite (SBS) Injection by dosing pump

By adding sodium bisulfite (SBS or SMBS), which is a reducer, to the water stream before an RO at the proper dose you can remove residual chlorine.

Granular Activated Carbon (GAC)

GAC is used for both removing organic constituents and residual disinfectants (such as chlorine and chloramines) from water. GAC media is made from coal, nutshells or wood. Activated carbon removes residual chlorine and chloramines by a chemical reaction that involves a transfer of electrons from the surface of the GAC to the residual chlorine or chloramines. The chlorine or chloramines ends up as a chloride ion that is no longer an oxidizer.

The disadvantage of using a GAC before the RO unit is that the GAC will remove chlorine quickly at the very top of the GAC bed. This will leave the remainder of the GAC bed without any biocide to kill microorganisms. A GAC bed will absorb organics throughout the bed, which is potential food for bacteria, so eventually a GAC bed can become a breeding ground for bacteria growth which can pass easily to the RO membranes. Likewise, a GAC bed can produce very small carbon fines under some circumstances that have the potential to foul an RO.

RO Data Trending and Normalization

The RO membranes are the heart of the RO system and certain data points need to be collected to determine the health of the RO membranes. These data points include the system pressures, flows, quality and temperature. Water temperature is directly proportional to pressure. As the water temperature decreases it becomes more viscous and the RO permeate flow will drop as it requires more pressure to push the water through the membrane. Likewise, when the water temperature increases the RO permeate flow will increase. As a result, performance data for an RO system must be normalized so that flow variations are not interpreted as abnormal when no problem exists. The normalized flows, pressures and salt rejection should be calculated, graphed and compared to the baseline data (when the RO was commissioned or after the membranes were cleaned or replaced) to help troubleshoot any problems and also determine when to clean or inspect the membranes for damage. Data normalization helps display the true performance of the RO membranes. As a general rule of thumb, when the normalized change is +/- 15% from the baseline data then you need to take action. If you don’t follow this rule then RO membrane cleanings may not be very effective at bringing the membranes back to near new performance.

RO Membrane Cleaning

RO membranes will inevitably require periodic cleaning, anywhere from 1 to 4 times a year depending on the feed water quality. As a general rule, if the normalized pressure drop or the normalized salt passage has increased by 15%, then it is time to clean the RO membranes. If the normalized permeate flow has decreased by 15% then it is also time to clean the RO membranes. You can either clean the RO membranes in place or have them removed from the RO system and cleaned off site by a service company that specializes in this service. It has been proven that offsite membrane cleaning is more effective at providing a better cleaning than onsite cleaning skids.

RO membrane cleaning involves low and high pH cleaners to remove contaminants from the membrane. Scaling is addressed with low pH cleaners and organics, colloidal and biofouling are treated with a high pH cleaner. Cleaning RO membranes is not only about using the appropriate chemicals. There are many other factors involved such as flows, water temperature and quality, properly designed and sized cleaning skids and many other factors that an experienced service group must address in order to properly clean RO membranes.

Reverse Osmosis: Summary

Reverse Osmosis is an effective and proven technology to produce water that is suitable for many industrial applications that require demineralized or deionized water. Further post treatment after the RO system such as mixed bed deionization can increase the quality of the RO permeate and make it suitable for the most demanding applications. Proper pretreatment and monitoring of an RO system is crucial to preventing costly repairs and unscheduled maintenance. With the correct system design, maintenance program, and experienced service support, your RO system should provide many years of high purity water.

If you need more information on how to use RO membrane, please contact us immediately with the following information:

KHANG NGOC ENVIRONMENT JOINT STOCK COMPANY

Address

Main office:

86 Dong Ho Street, Ward 4, District 8, Ho Chi Minh City, Vietnam

Tel: +8428. 37584648

Mobile: +84983.152.032

Branch office address:

C7/30C14 – Pham Hung Str. – Binh Chanh Dist. – HCM

Tel: +8428.37584648 / +8428. 62755032

Fax: +8428.37583936

Mobile: +84983.152.032

Factory & warehouse:

17 – Pham Hung street – Phuoc Loc ward, Nha Be district – Ho Chi Minh City, Vietnam.

Business

Business